UV in Commercial Pools

UV in commercial pools has proven to be the solution for dangerous RWI’s (Recreational Water Illnesses) and Chloramines (Chemical Irritants). UV Treatment is as natural as sunlight. More specifically, UV-C light is a natural component of the electromagnetic radiation that the Sun emits.

Safe and healthy swimming is a matter of clean water and air conditions. Whether you swim in a residential or public pool, poorly maintained water chemistry and air quality can make you sick.

UV in commercial pools has proven to be the solution for dangerous RWI’s (Recreational Water Illnesses) and Chloramines (Chemical Irritants). UV Treatment is as natural as sunlight. More specifically, UV-C light is a natural component of the electromagnetic radiation that the Sun emits. Much of the Sun’s radiation is absorbed by ozone in the Earth’s upper atmosphere, but some UV-C light passes through and acts as a natural disinfectant. UV-C light inactivates exposed microorganisms, including those found in surface waters.

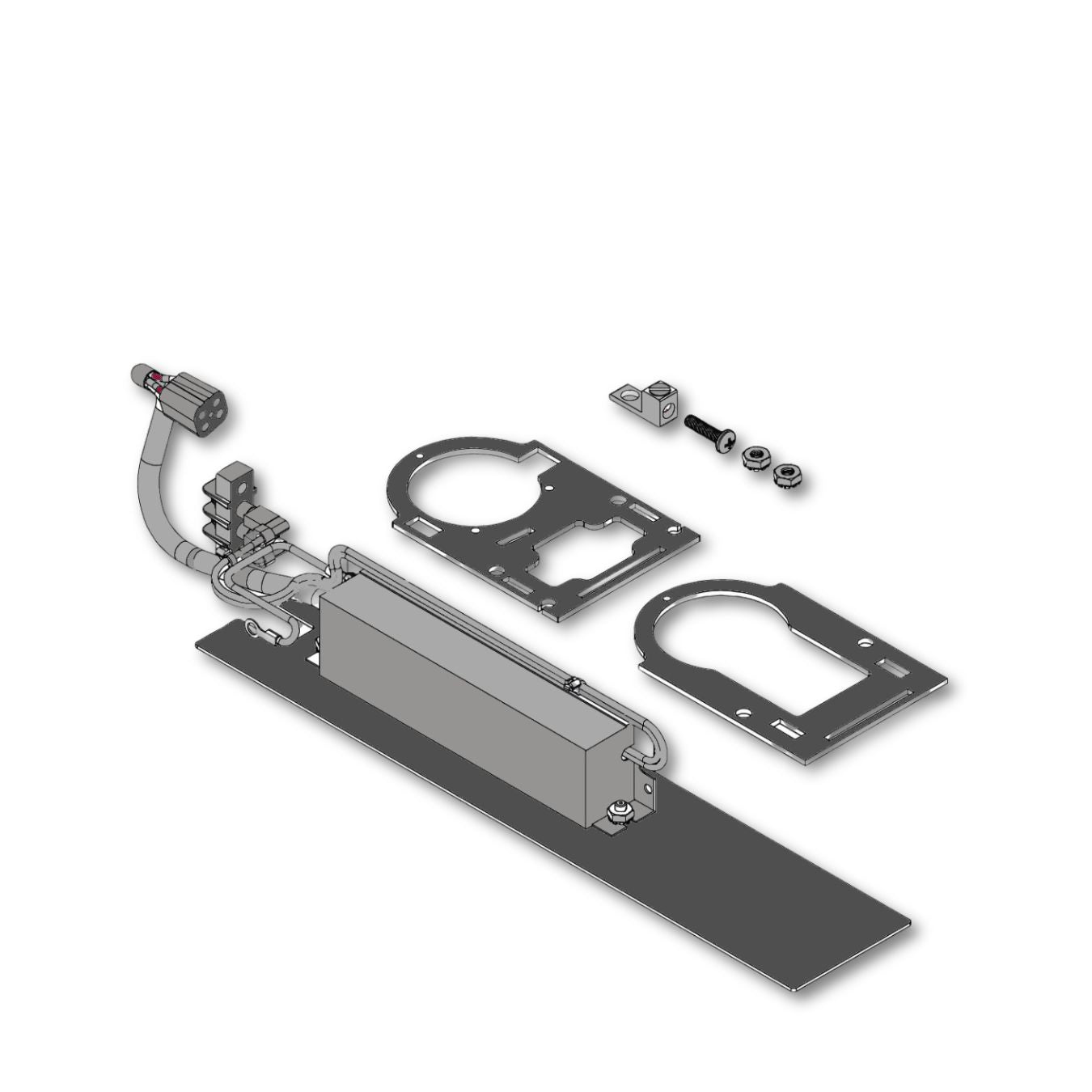

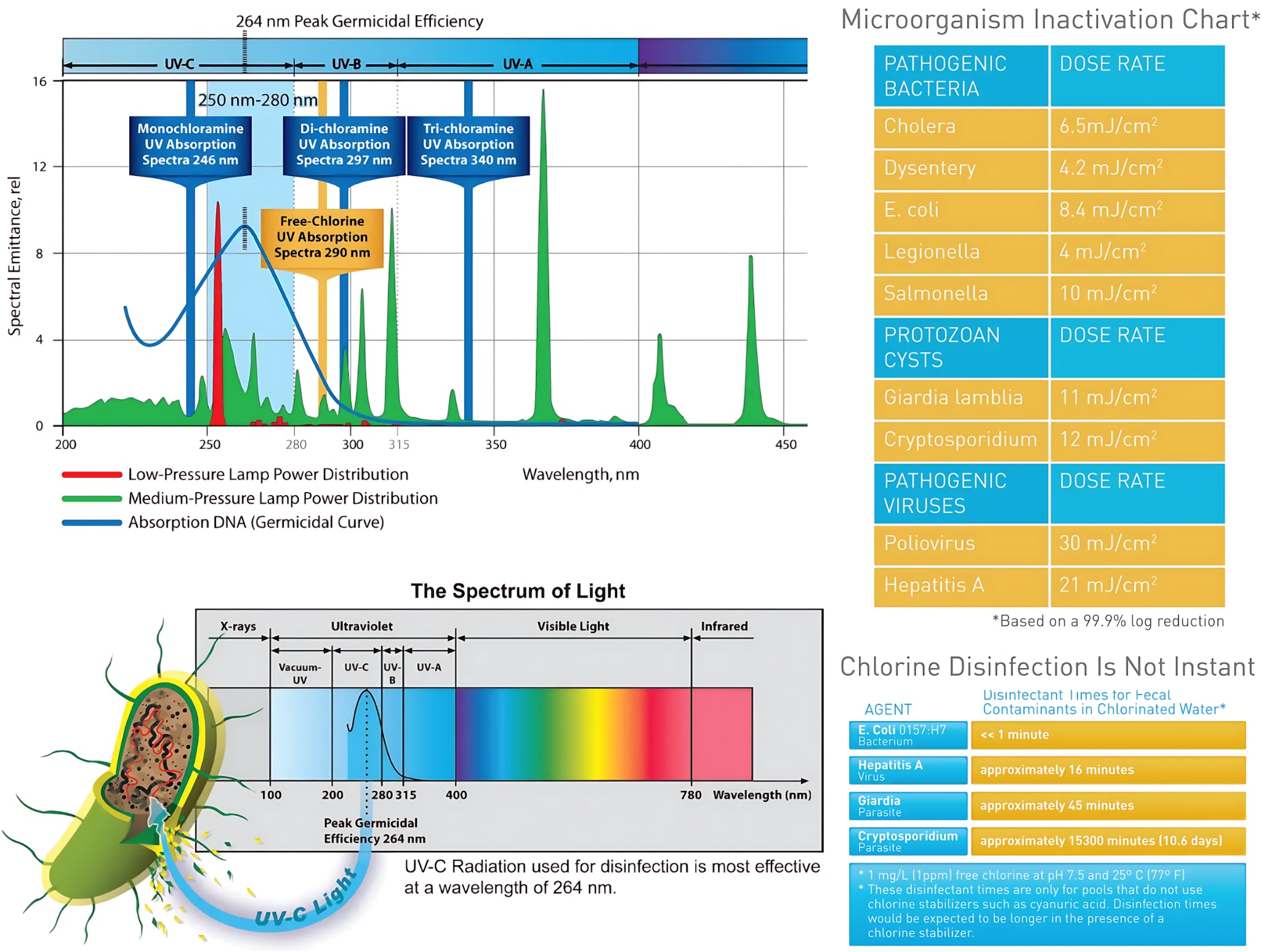

UV systems operate the same way. Inside a UV system, UV lamps emit UV-C light (wavelength range 240-280 nm). Waterborne pathogens in the water circulating through the UV vessel are exposed to the UV-C light for a determined amount of time and become inactivated.

UV is instant germicidal disinfection, Free Chlorine is not. UV disinfection inactivates germs (Cryptosporidium, Giardia and E. Coli.) most commonly associated with RWI’s. UV disinfection provides instant (single-pass) treatment unlike Free-Chlorine and ozone. UV systems are a “Green” Technology and deliver multiple benefits contributing to healthy swim water.

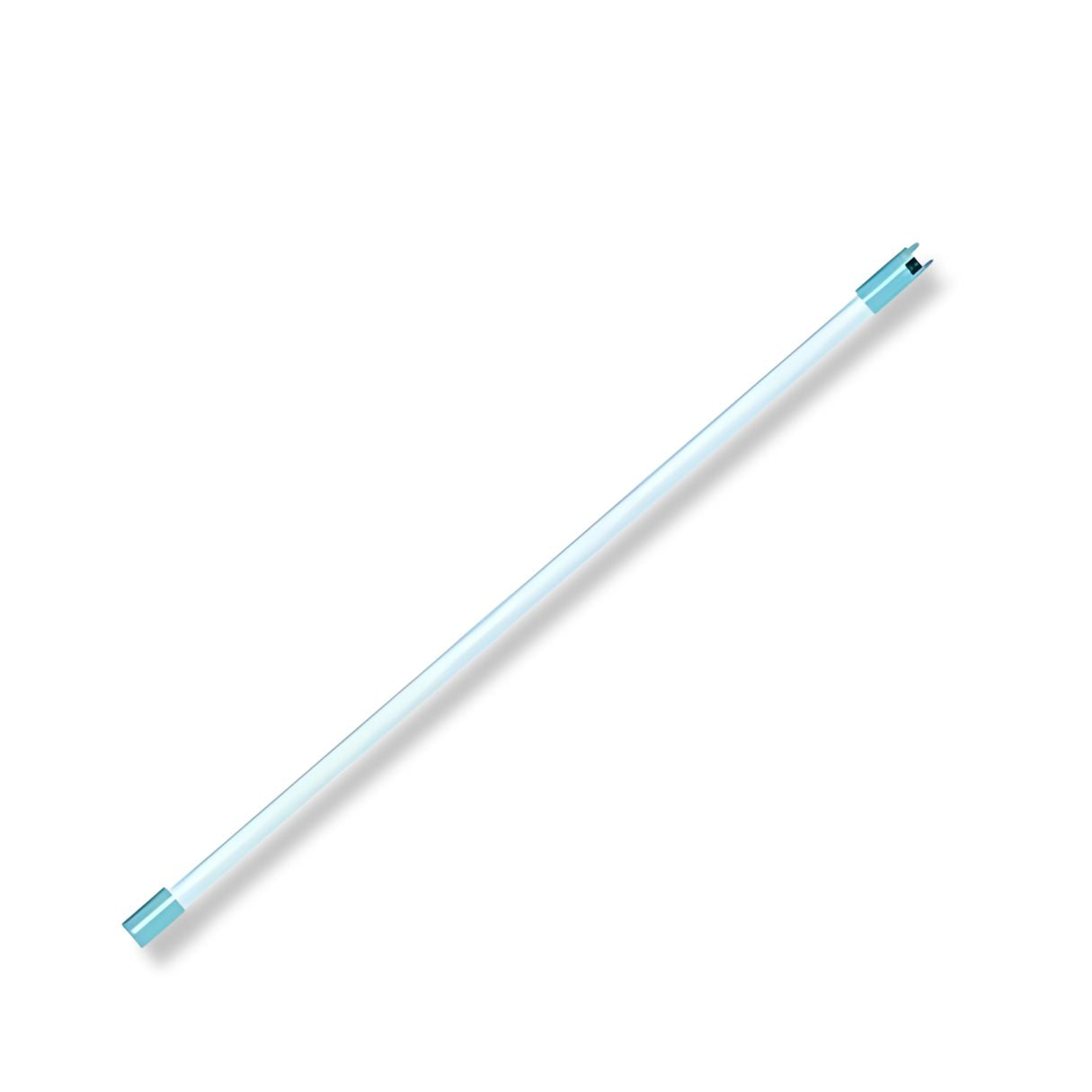

Two UV technologies exist: Low-pressure (LP) and Medium pressure (MP). Both UV technologies inactivate dangerous pathogens and irritating Chloramines but MP UV systems cost almost 3x more to operate than LP. In the past, Medium-pressure UV systems were believed to be more effective than Low-pressure due to MP’s high UV-C light output and compact package, but over the years LP UV lamp technology has improved to the point where LP lamps are now 5x more powerful than they were initially. Today, LP UV lamp technology continues to evolve and has significantly narrowed the gap of number of lamps required between MP and LP UV systems. The result is that LP UV in commercial pools systems now cost nearly 3x less to operate than MP UV systems. LP and MP UV lamps operate very differently. MP UV lamps convert 11-15% of their input electricity into UV-C light. LP UV lamps convert 35-40%, making them much more effective and cost-efficient at germicidal disinfection and Chloramine control.

Conserve Free-Chlorine

MP UV lamps decay Free-Chlorine which increases operational cost. LP UV lamps are proven to conserve Free-Chlorine by as much as 30%, saving you money.

Low Heat Output

LP Amalgam lamps operate at 180°F, MP lamps at 1,600°F. The extreme heat generated by MP UV lamps intensifies the problem of quartz sleeve fouling and creates the need for expensive and problematic quartz sleeve wiping systems. This ultimately complicates equipment maintenance. BioShield Amalgam UV lamps operate at a fraction of that heat output and do not require the addition of a quartz sleeve wiping system.

Longest Lamp-Life

LP UV lamp life of 12,000 hours, outlast MP lamps by as much as 3 times. Even with the need for additional lamps compared to MP, the high cost and short life of MP make LP UV up to 3 times less costly to maintain.

For example: a 288,000 gallon pool using a MP UV system, operating at 800 GPM, and delivering a UV dose to 60 mJ/ cm2, replaces MP UV lamps annually at a cost of $1,120 each ($3,300). Compare that to a LP UV system which replaces 7 lamps annually at a cost of $160 each ($1,120). The lamps are oversized at startup to accommodate a 20% degradation during the course of 12,000 hours